Spring 2010

39

for you, and another that will do the

knitting, weaving, or sewing. Ask if

the mill will send you samples of their

products. Be prepared to purchase

these and pay shipping. In the end,

it is well worth it, since it is almost

impossible to assess the quality of a

mill’s work without being able to hold

the end product in your hand.

2. What is the mill’s schedule for

producing the product you want?

Large commercial-sized mills can

process thousands of pounds of fiber

daily while the smallest mini-mills

might be limited to 20 or 30 pounds

a day. The amount of fiber that the

machinery can handle, and the size

of the mill’s staff, will determine how

quickly your fiber can be processed.

In addition, the mill will have times

when there are a lot of orders waiting

to be processed and other times when

work is slower. Be sure to ask both

questions – how long will the job take

and how many jobs are ahead of

yours? It will not help you to send

your fiber to a mill that has a six-

month backlog of other jobs if you are

expecting the finished product to be

returned in a few weeks.

3. What are the costs for processing

and what is included in each step?

I have found that while the rates for

processing are somewhat similar across

the country, it is important to ask

what is included. For example, some

mills routinely wash fiber prior to

spinning, and there is an extra cost for

this. Some mills only wash the fiber if

you specifically request that step. The

sizes of skeins that are produced when

yarn is spun vary from 1.5 ounces to

7 ounces, so if you get a price for spin-

ning that is per skein you will want to

ask how big the skeins are. Does the

mill wash, stretch, or steam the skeins

after they are spun? If you are having

batts made up, what size are the fin-

ished batts? One mill may be quoting

you a price per batt for 24-inch batts

and another for 48-inch batts. The

more detail you get from each mill, the

more it will help determine where you

get the most return for your money.

4. When does the mill expect

payment?

Some mills will estimate the costs up

front and ask for payment in advance.

Some will ask for partial payment up

front and the rest at the completion of

the job. Some will bill you when the

processing is completed. Some take

checks and others require credit cards.

For your planning purposes, be sure

you know when and how you need to

pay for the work.

5. Does the mill staff have any sug-

gestions?

Fiber processors are professionals with

lots of hands-on experience. Through

the years, they have experimented with

more types of fibers and more process-

ing options than most of us ever will.

Why not use their knowledge to

improve your own processing venture?

Sure, you would love to have yarn

made from 100% alpaca, but depend-

ing on what you want to make out of

that yarn, an alpaca blend might be

more suitable. Fiber processors can

suggest the right weights of yarn,

appropriate blends, and discuss color

options with you. Don’t be afraid to

ask the pros!

6. How does the mill want the fiber

shipped?

Many mills have developed criteria for

fiber shipping, covering everything

from the size of shipping box to the

type of bag that is used inside the

box. The postal service has different

requirements than do private shipping

companies. If your mill is across a

national border, you will have customs

regulations to deal with. By asking

ahead of time, you can eliminate

delays caused by incorrect packaging.

I have found that there is no such

thing as too many labels when ship-

ping boxes of fiber. Placing shipping

labels inside the boxes as well as out-

side is smart in case boxes break open

or the original label gets smeared.

Boxes can get separated in transit.

Labeling boxes as “Box 1 of 3,” “Box

2 of 3,” etc., will help the mill to

know when all of your boxes have

arrived. Be sure to provide the mill

with your correct shipping address,

especially if your billing and shipping

addresses are not the same.

Your relationship with the mill that

will process your fiber is a primary key

to your success. In order to find a fiber

processor that meets your expectations,

you must know in advance what those

expectations are. The more time you

spend thinking about your goals for

fiber processing, and communicating

those goals to the staff at your mill,

the better the outcome will be, for

both you and the mill. In the end,

everyone wins when your beautiful

alpaca fiber is turned into beautiful

end products for a reasonable cost in

a timely fashion. You are happy, the

fiber processor is happy, and your

customers are happy… win/win/win,

through good communication.

Deb Hill, Cloud Dancer Alpacas, has been

breeding alpacas since 1996, first in Arizona

and now in Montana. After two decades of

small business and management experience,

Deb left the private sector and was elected to

public office in 2000. She served as a County

Supervisor for eight years, but has now

returned to the ranch as a full-time alpaca

owner. She can be reached at clouddancer@

infomagic.net or in care of

Alpacas Magazine.

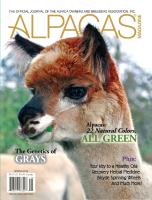

Which mill is right for your fiber and your end products? Do you want your

fiber handspun and handmade? Or do you need a larger mill such as this to

create large numbers of items?