Spring 2010

37

um-fine fleeces, or even slightly coarse

fleeces if the item will be worn over

other clothing, so the coarseness is

mitigated. Coarser fibers are stronger,

and suitable for clothing that will get

hard wear, such as socks or work

gloves. Yarn, felt, batts, or roving can

be made from any type of fiber.

Knowing what quality of fiber you

have to work with, and how much you

have, will help you to select appropriate

finished products. The old saying “You

cannot make a silk purse from a sow’s

ear” applies!

4. How much can you afford

to spend for processing?

Your budget will play a big part in

determining the end products that

you make from your fiber. The more

processing that is required to create

the finished product, the more it will

cost you. The least expensive option is

to have your fiber washed and carded

into batts or roving. You will get a

product that can be sold to spinners

and other handcrafters, or which you

can use for your own fiber arts projects,

at the minimum processing cost. On

the other hand, if you have your heart

set on making sweaters, be prepared to

pay a much greater amount, since the

fiber will need to be cleaned, carded,

spun, and knit to your design specifi-

cations. You will need to assess

whether you can afford the extra pro-

cessing costs, and whether it makes

financial sense. If you plan to sell the

final product but the production costs

are too high for you to cover with the

item’s sales price, it might be better to

settle for a less expensive end goal.

O

nce you know the quality and

quantity of fiber that you have

available, the type of product you want

to have it made into, and your budget

for processing, you are ready to talk to

the fiber processors. You can find fiber

processors through Internet searches,

by asking other breeders for referrals,

by checking with fiber guilds, or from

AOBA’s

Directory of Fiber Resources.

When you have identified several

mills that seem suitable, you can begin

the task of contacting the staff at each

and asking questions that will help

you to select the best partner for your

fiber processing venture.

The goals of a good fiber processor

are very similar to yours. The fiber

processor wants to create the best

quality product for the most reasonable

price. Their business success is based

on making you happy. In order for

them to do that, you need to be able

to tell them specifically what you are

looking for. If they cannot do it, they

will let you know. Good communica-

tion is the key to keeping the fiber

producer and the fiber processor on

the same page.

Your goal is to find a partner that

you can trust to produce the quality

of product that you want, with the

minimum of wasted fiber, and for the

best price. You may need to test several

partners before you find the one that

works best for you. If it is possible,

visit each mill in person. If you can’t

do that, then create a matrix where

you can list each mill, the types of

services they offer, and the pricing.

This information will be extremely

useful for you in the future, so keep

the information in a database where

you can find it again when you need

it. Minimally, you should ask the

following questions of each mill that

you are thinking of working with:

1. Does the mill have the capacity

to produce the type of product

you want?

Most mills can create rovings, sliver,

batts or yarn. A few also produce

finished products such as hats, gloves,

scarves, throws, or socks. Hardly any

are making fit goods (those items of

apparel that come in sizes), so if you

want sweaters, coats, or other goods,

you will likely need to find one

processor to create the yarn or fabric

“I know that you believe you understand what you

think I said, but I’m not sure you realize that what you

heard is not what I meant.”

Robert McCloskey, author and illustrator

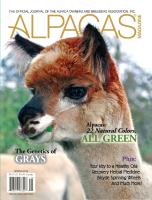

Checking out fiber quality at the mill.

Kim DeVos